Monolithic Insulating Joints

CCE supplies the complete range of monolithic insulating joints (MIJs) that are used for the sectioning of main pipelines in the oil, gas and water industries to ensure full efficiency of cathodic protection systems and ensure electrical safety. They serve as a positive, leak-proof, block against the flow of electric current in all piping systems.

CCE and our suppliers can design custom MIJs to cater for ‘heavy’ conditions such as external loads and more.

One of the best ways to manage electrical resistance between pipeline sections and adjoining structures is to use purpose-built monolithic insulating joints. Not only are they used for sectioning oil, gas, water and petrochemical pipelines but they also do not interfere with active corrosion prevention systems. Our range of MIJs are superior to insulation kit gasket assemblies because they are pre-assembled, tested and ready to be welded and installed where required.

MIJs also serve as a positive, leak-proof, block against the flow of electric current in all piping systems. CCE and our suppliers can design custom MIJs to cater for any situation.

Zunt Italiana has designed and manufactured monolithic insulating joints for over two decades, which is why we supply their quality products. These components are designed, manufactured and tested in full compliance with the most stringent international standards and client specifications. Fittings are available in flanged, weld/weld and screwed ends.

High pressure monolithic insulating joints for water, gas, oil and petrochemical industry Insulating joints for high temperature fluids, sour service applications, conductive fluids and more

- Isolation spools

- Low pressure service joints

- Pre-assembled insulating flanges

- Insulating kit for flanges

- Steel polyethylene transition fittings

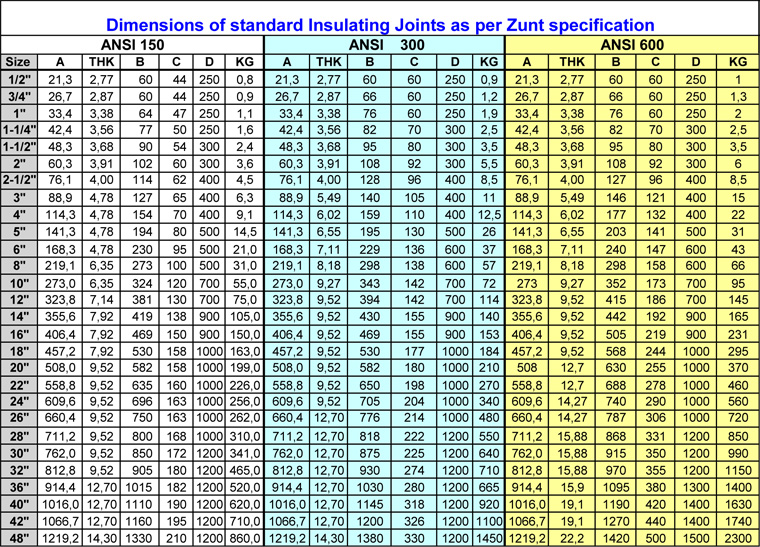

STANDARD PRODUCTION RANGE

| SIZE | from ½” to 120″ and over |

| RATING | from ANSI 150 up to ANSI 2500 and over |

TECHNICAL FEATURES (Zunt standard)

| Design Factor | 0.6 |

| Temperature range | -10°C / 70°C |

| Hydrotest pressure | 1.5 times the Design Pressure |

| Dielectric Strength Test | > 3 kV for 1 min. – 50 Hz AC |

| Electrical Resistance Test | in dry conditions > 25 MOhm – 1000 V DC |

| Coating / Lining | epoxy resin |

| N.D.E. | MPI, UT, X-Rays, Dye Penetrant on welds (as applicable) |

Design Calculations to ASME VIII Div. 1 App. 2

WPS, PQR, WPQ to ASME IX (other codes on request), EN 15614, EN 15609, EN 288

Applicable standards: NACE, DM 17/04/2008, UNI 10285, UNI 11105, EN 1594

PED / ATEX compliance on request

- PATENTED independent double sealing system applied from 16” #600 and over (also available on smaller sizes/ratings on request)

- Dimensions are indicative only and may be altered without prior notice

- Pipe pups : API 5L / ISO 3183 / EN 10208-2 / ASTM A106 / ASTM A333

- Alternative wall thickness and quality of pipes available on request

- Bevelled ends to API 5L

- Dimensions, weights and technical features of insulating joints over size 48″ Class rating ANSI 600 will be provided with a specific bid

Custom Made Production

Manufactured in compliance with the client specification

PRODUCTION RANGE

| SIZE | from ½” to 120″ and over |

| RATING | from ANSI 150 up to ANSI 2500 and over |

SPECIAL FEATURES (On request)

| Design Factor | as per client’s specification |

| Low Temperature design | down to -50 °C |

| High Temperature design | up to +165 °C |

| Dielectric Strength Test | up to 20 kV for 1 min. 50 Hz AC |

| Electrical resistance Test | in dry conditions > 200 MOhm – 1000 V DC |

| Coating/Lining | as per client’s specification |

| Finite element analysis | on request |

| PED / ATEX compliance | on request |

EXTRA TESTING (on request)

- Helium Test

- Torsion test

- Hydro-thermo-bending test

- Electrolytic immersion test

- Hydraulic fatigue test

- Air leak test

- Vacuum test

Monolithic Insulating Joints and More

Quality cathodic protection materials used correctly will prolong the lifecycle of your strategic assets and structures. The team at CCE can source everything you need from anodes and transformer rectifier units to reference electrodes, cabling, monolithic insulating joints and more.

We also offer specialised engineering and field services to assist in the installation, testing, troubleshooting and decommissioning of CP equipment. Contact us today to discuss your project requirements.